Ultrasonic gas flow meter matching layer

Classification:

Ultrasonic gas flow meters are widely used in various industries for their high accuracy and reliability in measuring gas flow rates.

Product Description

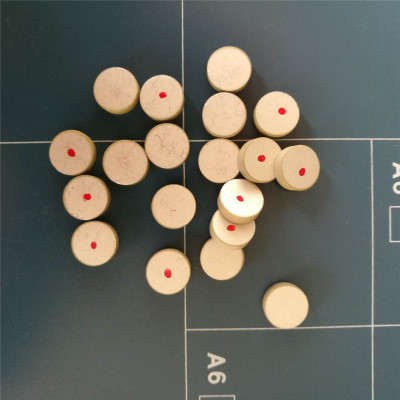

Ultrasonic gas flow meter matching layer

Ultrasonic gas flow meters are widely used in various industries for their high accuracy and reliability in measuring gas flow rates. One key component of an ultrasonic gas flow meter is the matching layer, which plays a crucial role in enhancing the performance of the meter.

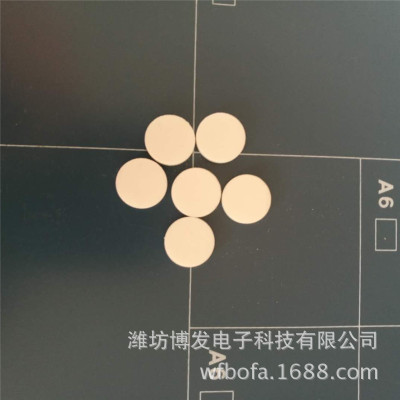

The matching layer is a thin, acoustic impedance-matching material that is placed between the transducer and the gas flow to improve the transmission of ultrasonic waves. It is designed to minimize the reflection of ultrasound waves at the transducer-gas interface, allowing for better signal transmission and reception.

The main purpose of the matching layer is to ensure that the ultrasonic waves are effectively transmitted into the gas flow, where they can accurately measure the flow rate. By reducing the reflection of waves, the matching layer helps to improve the signal-to-noise ratio of the meter, resulting in more accurate and reliable measurements.

In addition to improving signal transmission, the matching layer also helps to protect the transducer from damage or wear caused by the harsh conditions of the gas flow. It acts as a barrier between the transducer and the gas flow, shielding the sensitive components of the meter from any potential harm.

The material used for the matching layer is carefully selected based on its acoustic properties, such as impedance and absorption coefficient, to ensure optimal performance of the gas flow meter. Common materials used for matching layers include polymers, ceramics, and composites, each offering unique advantages in terms of durability, flexibility, and acoustic properties.

Proper design and placement of the matching layer are crucial for the overall performance of the ultrasonic gas flow meter. The thickness, density, and composition of the matching layer must be carefully calibrated to achieve the best results in terms of signal transmission and accuracy.

In conclusion, the matching layer is a critical component of an ultrasonic gas flow meter, playing a key role in enhancing the meter's performance and accuracy. By minimizing signal reflection, protecting the transducer, and optimizing signal transmission, the matching layer helps to ensure reliable and precise measurements of gas flow rates in various industrial applications.

Organic chemical RY series thermal fuse is a non-resettable disposable thermal protection device. The product has exquisite appearance and structure, good sealing performance, sensitive and reliable operating temperature, small current impact and vibration resistance. It is suitable for overheat protection of household appliances and industrial equipment (such as electric fans, motors, transformers, electric rice cookers, electric frying pans, disinfection cabinets, electric hot water bottles, etc.). The thermal fuse is connected in series in the equipment circuit. When the temperature rises to the set protection value due to the abnormal operation of the equipment, the thermal fuse acts to cut off the circuit to prevent safety accidents. RY series thermal fuse temperature sensitive alloy composition deviation is small, has good stability and reliability.

Key words:

Ultrasonic gas flow meter matching layer

Recommended

Tire balancer sensor plays a crucial role in ensuring the safety and performance of vehicles.

A guitar is a popular musical instrument that is commonly used in various music genres worldwide.

Level gauge sensors are essential components in various industries and applications where accurate measurement and monitoring of liquid levels are required.

A gas flow sensor is a device used in various industries to measure the flow rate of gases through a particular system or process.

Welcome your message consultation

If you have any questions or concerns, please feel free to call or email us at any time, and we will reply to you as soon as possible!